The possibilities are

endless and

the solution is strong

Steel has so many amazing properties that we do not hesitate to call it the building material of the future. And the present.

One of the great advantages of using steel in construction is that, compared to other building materials, you get a unique combination of high tensile strength and low weight. It is also much easier to transport steel than, for example, heavy concrete elements.

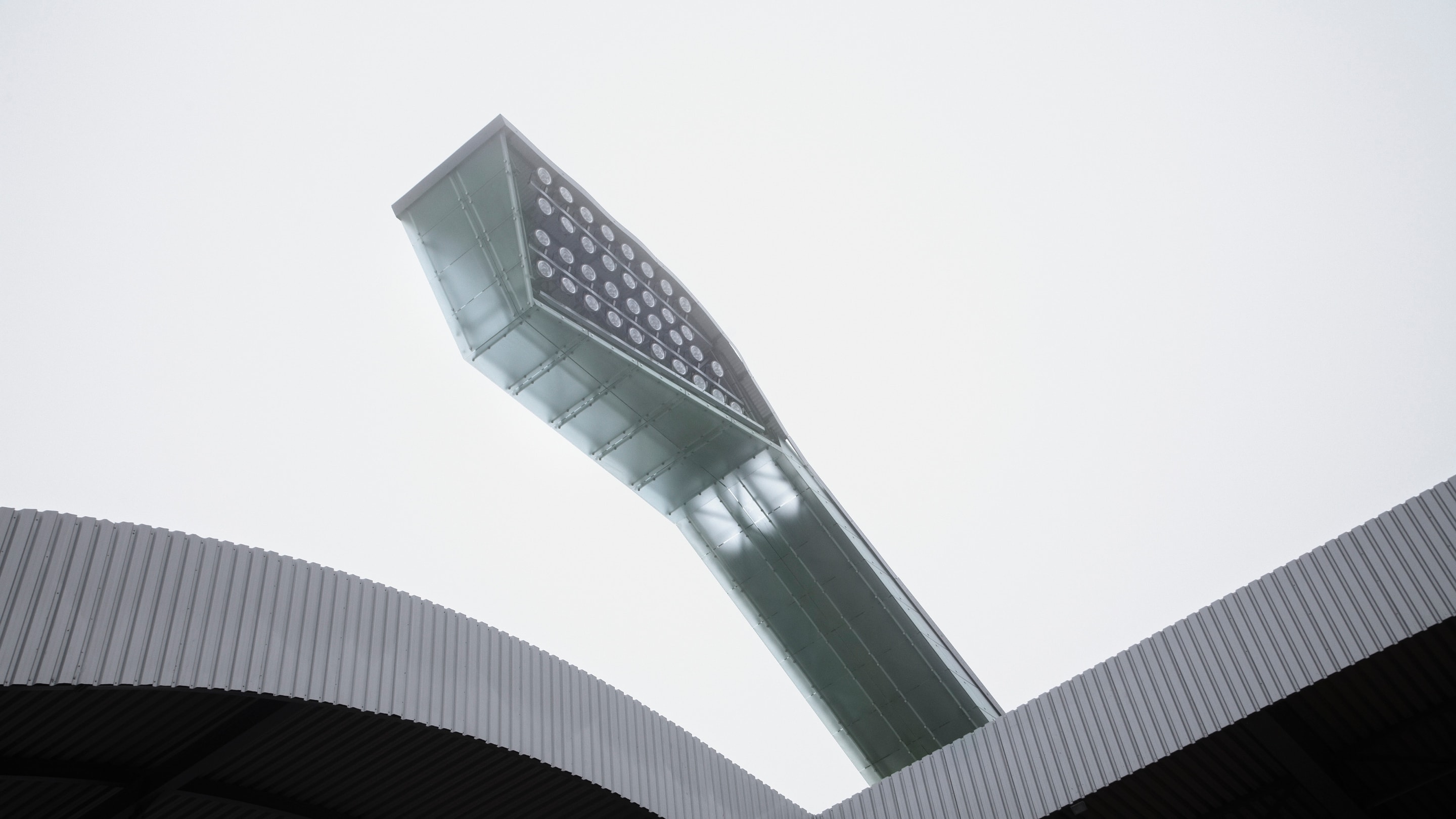

Steel is also a very flexible choice. This advantage offers great architectural freedom, making steel the preferred choice for many architects. A preference for steel is particularly evident when creative architects have to design distinctive company headquarters and other larger buildings with a bold edge and character.

In terms of economics, steel frequently offers the best business case. Both in the short and long term.

Finally, it should be noted that steel has very high recyclability. In fact, you could reasonably say that the steel in a building is just on loan. After it has served its purpose in the building, it can be returned as scrap and re-used in new applications. Given the continual advances in refinement methods, steel can even be upcycled and resurrected as a new and even better material.

CSK is one of Denmark’s leading suppliers of steel structures. We cover the entire value chain, and can therefore contribute knowhow and expertise at all phases, from design to final installation.

.png)

.png)